Introduction to Floor Sanding and Polishing

The floor sanding and polishing process is a way of rejuvenating and preserving the natural beauty of wooden floors. Timber floors are an elegant choice and timeless beauty for Brisbane homes and commercial spaces. The longevity of hardwood floors depends on the care they receive and maintenance strategies opted for their shine and resilience. Floor sanding removes the top worn-out layer of the timber, while floor polishing gives shine and protection.

Budget Floor Sanding Company has been in the floor sanding and polishing business for many years. We ensure exceptional results for homeowners and businesses.

Below is a comprehensive guide about the floor sanding and polishing process and insights into the tools, techniques, and benefits. Gaining insight into the subtle details of the procedures will help you recognize the skills and craftsmanship and ensure that your floors look impeccable for years.

Why Timber Floor Sanding and Polishing is Necessary?

Foot traffic, furniture movement, and general aging can cause scratches, discoloration, and unevenness in timber floors. Some common issues that necessitate floor sanding and polishing include:

- Uneven surfaces: Temperature and humidity changes cause the timber to expand and contract, which can cause gaps, warping, or cupping of the floorboards.

- Fading and discoloration: UV rays from sunlight cause fading of the timber, while moisture exposure can lead to stains or dark patches on the floor.

- Wear and tear: The protective finish can wear down in high-traffic areas due to everyday use.

- Scuffs and Scratches: Pet claws, furniture dragging, and high foot traffic can scratch the floor.

Sanding the floor removes these imperfections while polishing restores the shine by adding a protective layer.

Floor Sanding Preparation

All trade work should be completed before any floor polishing or floor sanding process takes place in your Brisbane home. Our floor sanders will require electricity and lighting to start and complete your polished timber floors. Newly purchased homes often need to have the electricity reconnected before we can commence refinishing any wooden floors.

It is ideal to have all painting completed, except for the final coat on the skirting boards as our floor sanding equipment will come into contact with the skirting boards during the sanding and polishing process.

Any Electrical or Gas appliances should be disconnected or turned off.

Timber floor finishes can sometimes seep through the timber tongue and groove boards, so we advise moving or covering items stored under the wooden floors being polished.

All floor coverings and furniture must be removed from the area requiring sanding. Budget Floor Sanding can organize floor covering removal at an extra cost if needed. Undertaking the removal of all tacks and staples yourself will reduce your floor sanding and polishing price.

The Floor Sanding and Polishing Process

The Floor Sanding process begins with punching exposed nails below the surface of the wooden floors. If the timber floor has an existing coating, we then remove the coating with coarse sandpaper, at this point, we will repair or replace floor boards that require attention.

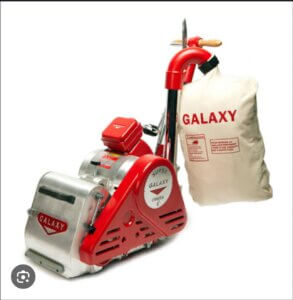

The timber floor is then sanded with finer grades of sandpaper until they are smooth and ready for the coating to be applied. Our team uses the best machines in timber flooring industry, the Canadian Galaxy drum machine.

We now apply the first coat on the timber floor and this coat must dry overnight. Before we apply further coats the floor Is finely sanded with a buffering machine. Generally, we apply 3 coats to the floor and the process takes 3-4 days to be completed. We offer a range of floor finishes depending on your preference of floor finish. Floor finishes include gloss, satin, and mat. We have a selection of solvent-based, polyurethane, environmentally friendly water-based, and traditional oil-based finishes.

Please contact Matt to discuss your floor sanding and polishing requirements. Find more details on our Timber Floor Finishes page.

If you require the best floor sanding and polishing services throughout Brisbane, contact Glenn to discuss all your floor sanding and timber floor finishing options that suit your style, budget, and time frame. Sanding wood floors is our specialty, so why don’t you find out what we can do for you?

Take a look at the beautiful timber floors Budget Floor Sanding has transformed, in our Timber Floor Gallery.

Detailed Floor Sanding Process

Assessment of the floor

In floor sanding, initial assessment and consultation is the first step. Our professionals visit the site to inspect the condition of your wooden floor. This step is significant in analyzing the scope of work and identifying specific issues such as:

- Previous Coatings: Any existing finish that needs to be removed before sanding.

- Surface damages: Scratches, dents, scuffs, and fading affect the aesthetic appeal of the floor.

- Gaps between floorboards: Gaps and cracks between the floorboards compromise the structural integrity.

The initial assessment helps the team choose the appropriate sanding technique and the best finish for your floor.

Preparation of the Area

The key to a successful floor sanding process is floor preparation. Off electrical and gas appliances before starting the sanding process.

The following are the preparatory steps for sanding and polishing the floor:

- Clearing the clutter: All rugs, furniture, and decorative items are removed or covered with protective sheets to create an obstruction-free workspace.

- Complete the wall painting: It is ideal to complete the wall painting before starting the sanding process. Leave the final coat on the skirting boards, as our floor sanding equipment will come into contact during the sanding and polishing process.

- Electricity and Lighting Provision: Our floor sanders will require electricity and lighting to start and complete your polished timber floors. Newly purchased homes often need to have the electricity reconnected before we refinish wooden floors.

- Protecting other areas of the house: Dust can spread during sanding in the home, so other rooms are sealed off with plastic sheeting to prevent dust accumulation. Timber floor finishes can sometimes seep through the timber tongue and groove boards, so we advise moving or covering items stored under the wooden floors being polished.

- Inspecting for loose nails and screws: The team checks for loose boards, protruding nails, or other damages and repairs them to ensure the sanding smooth and effective sanding process. If the timber floor has an existing coating, we remove the coating with coarse sandpaper. At this point, we will repair or replace floorboards that require attention.

- Choosing the Right Sandpaper Grit: Different grit sandpapers are used depending on the floor condition. Heavily damaged or coated floors may require a coarse grit, while finer grits for a smooth finish.

Budget Floor Sanding can organize floor covering removal at an extra cost if needed.

Floor Sanding

The sanding process is the heart of the restoration work. It involves using specialized machines to eliminate scratches, stains, and old finishes. Our team uses the best machines in the timber flooring industry, such as the Canadian Galaxy drum machine. The sanding process prepares the floor for polishing.

The floor sanding process involves

- Belt Sanding: The first stage involves a powerful belt sander that works efficiently on large, flat areas. It removes the old finish and smooths out the wood. A coarse grit sandpaper initially separates the bulk of the damaged top layer and coats the floor. The machine must be handled carefully to avoid uneven sanding.

- Edge Sanding: Edge sander sands along the perimeter, where the belt sander cannot reach. It is a small and easy-to-handle machine that sands the edges and corners of the space. The team ensures consistency in the sanding, paying close attention to the edges and corners.

- Corner Sanding: To ensure a flawless finish, detail sanders or hand tools are employed for difficult-to-reach areas. Budget Floor Sanding professionals use precision tools to maintain consistency throughout the room.

- Fine Sanding: Fine-grit sandpaper is used to refine the surface, once the bulk of the work is done with coarse-grit sandpaper. It creates a smooth, even finish that’s ready for polishing. This stage removes any residual scratches or imperfections.

Dust Control

Dust spreading is a common issue during floor sanding. It is a nuisance and health hazard. Our advanced dust containment system reduces airborne particles, making the process cleaner and safer.

- Dustless Sanding: Dustless sanding machines are equipped with vacuum systems to capture dust at the source. It ensures a healthier environment and a minimal mess during the project.

- Post-Sanding Cleaning: After the sanding, our team will clean the area with a vacuum and cloth. The floor, walls, and windows are cleaned to remove dust and wood particles. Post-sanding cleanup prepares the floor for the next step.

Detailed Floor Polishing Process

Floor finishing or polishing enhances its beauty and durability. The process of polishing involves applying protective coatings and finishes. It gives the floor a glossy or matte look and protects it from wear, moisture, and UV damage.

Right Finish for the floor

There is a range of finishes available to suit different preferences and flooring types. The choice of finish depends on factors such as the amount of foot traffic the area receives type of wood, and the desired aesthetic. Floor finishes include gloss, satin, and mat. We have a selection of solvent-based, polyurethane, environmentally friendly water-based, and traditional oil-based finishes.

- Natural Oils and Waxes: Ideal for people who prefer a natural look for their floors. They penetrate the wood for nourishment and protection. They may require more frequent maintenance than synthetic finishes.

- Hard Wax: It is a combination of natural oils and synthetic resins. Hard wax oils provide a protective layer while maintaining the natural look of the wood. They are easy to maintain and offer good durability.

- Water-Based Polyurethane: They have quick drying time, low VOC content, and are eco-friendly. This finish provides a durable, clear coat that enhances the natural color of the wood.

- Oil-Based Polyurethane: It is highly durable and suitable for high-traffic areas and Offers a warm, amber tone. However, it has a longer drying time and emits more fumes compared to water-based options.

Application of floor polish

The application process starts after the sanding is completed and the floor is cleaned. The process varies slightly depending on the type of finish used.

- Wood Sealing: Wood sealant prepares the floor to take the finish well. The sealant provides an extra layer of protection. This step is crucial for porous woods like pine or oak.

- First Coat: The first coat is applied using high-quality applicators. The team ensures an even layer across the entire floor. Depending on the type of finish, this coat requires a day to dry completely.

- Buffing: The floor is lightly buffed using a fine abrasive pad as the first coat dries. This step ensures that the next coat adheres properly and smooths out any imperfections.

- Second Coat: Dust is removed before the next coat is applied. The second coat gives extra shine and protection to the floor. Generally, we apply 3 coats to the floor and the process takes 3 to 4 days to complete. Each coat is carefully spread, ensuring there are no streaks, bubbles, or missed spots.

- Final Buffing: the team may perform a final buff after the final coat dries to enhance the floor’s sheen and smoothness. A thorough inspection ensures that the floor is flawless, smooth, and ready for use.

Curing and Drying Time

The floor finish drying and curing times vary depending on the type of finish used. Oil-based finishes may take 6-12 hours to dry and up to a week to cure completely, while water-based finishes typically dry within 2-4 hours and cure fully within 2-3 days. Avoid placement of furniture and walking before the floor dries.

Benefits of Professional Floor Sanding and Polishing

Budget Floor Sanding’s professional services offer numerous benefits that go beyond what DIY floor restoration can achieve. Some key advantages include:

Increased Aesthetics

Sanding and polishing enhance the grain patterns and color and restore the natural beauty of wooden floors. Whether you prefer a matte, natural look or a high-gloss finish, professional polishing by Budget Floor Sanding brings out the best in your timber floor.

Promising Longevity

Regular sanding and polishing extend the lifespan of timber floors by protecting them from damage caused by everyday wear and tear. Your floors stay strong and durable for years to come through sanding and polishing.

Increased Property Resale Value

Well-maintained wooden floors add significant value to a property and increase its resale value. Beautifully polished floors can be a key selling point when you plan to sell or rent out your home.

Healthy Indoor Environment

Dustless sanding process and finishes with low-VOC create a cleaner and healthier indoor environment. Properly sanded and sealed floors reduce the accumulation of dust, allergens, and dirt and are also easier to clean.

Customization Liberty

Budget Floor Sanding offers customization options from selecting the type of finish that matches your style and the overall décor of your space.

Special Considerations for Brisbane Homes

Brisbane’s climate plays a great role in the maintenance and longevity of wooden floors. Wood expands and contracts leading to the formation of gaps, warping, or moisture damage. Budget Floor Sanding understands these challenges and tailors its services to address them effectively.

Moisture and Humidity Control

Changes in humidity in the air have a significant impact on the structural integrity of timber floors. Budget Floor Sanding ensures that moisture levels are checked and controlled During the sanding process, to prevent problems such as cupping or crowning after the polish is applied.

Protection from UV rays

Brisbane’s sunny weather means that timber floors are exposed to sunlight, especially decks and verandahs. UV rays in sunlight can cause fading and discoloration. The application of UV-resistant finishes protects your floors from sun damage, keeping them vibrant for longer.

Maintenance Guidelines for Brisbane Homes

To extend the life of your newly sanded and polished floors, it’s important to follow proper maintenance practices. This includes:

- Avoiding excessive moisture on the floor by cleaning up spills immediately and avoiding using excessive water when cleaning.

- Use area rugs and mats in high-traffic areas to prevent scratches and warping of the floor. Avoid walking on the floor with heels.

- Avoid using harsh chemicals or abrasive cleaners on polished surfaces. Use a mild detergent and chemical-free liquid cleaner for cleaning the floor.

- Scheduling periodic re-polishing to refresh the protective layer and maintain the floor’s beauty.

- Use curtains or blinds to limit direct sunlight exposure. UV rays can cause the timber to fade over time.

Budget Floor Sanding’s Commitment and Professionalism

Our company takes pride in its environmentally conscious approach to floor restoration and repair. We ensure minimal impact on the environment by using eco-friendly, low-VOC products. The exceptional results are due to dust-free sanding technology and dedication to work. The efficient working reduces waste and air pollution, contributing to a greener, cleaner Brisbane.

Why Choose Budget Floor Sanding?

Budget Floor Sanding stands out in Brisbane’s flooring industry due to the

- The expertise and Experience we provide, ensure high-quality results for every project.

- State-of-the-art advanced Equipment that provides dust-free sanding and high-end polishing services.

- Local Knowledge about Brisbane’s climate helps us to offer tailored services that address local flooring challenges like humidity, wear, and sun exposure.

- Budget-friendly services: The name Budget Floor Sanding reflects its commitment to providing high-quality services at affordable rates. Our services are attainable by a diverse range of customers.

Conclusion

Whether you’re renovating your home or looking to maintain your commercial property, a reliable, efficient, and affordable solution for all your floor restoration needs is sanding and polishing. These processes enhance the natural beauty of the wood while protecting it from the elements.

Investing in professional floor sanding and polishing can improve the aesthetics of your space and extend its life. It can also add value to your property and create a healthier living environment.

Frequently Asked Questions About Floor Sanding And Polishing Process Brisbane

How long does the floor sanding and polishing process take?

The floor sanding and polishing process typically takes 3-4 days to complete. This includes the time required for sanding, applying multiple coats of finish, and allowing each coat to dry properly.

Do I need to remove all furniture before the floor sanding process?

Yes, it is recommended to remove all furniture from the area that requires sanding. This ensures that the floor sanders have unobstructed access to the entire floor surface, allowing for a more thorough and even sanding.

Can Budget Floor Sanding assist with floor covering removal?

Yes, Budget Floor Sanding can assist with the removal of floor coverings, such as carpets or rugs, for an additional cost. However, if you prefer to reduce the overall cost, you can undertake the removal of tacks and staples yourself before the sanding process begins.

What happens to exposed nails on the wooden floor during the sanding process?

During the floor sanding process, any exposed nails on the wooden floor are punched below the surface. This ensures a smooth and even surface for sanding and prevents damage to the sanding equipment.

What type of machines are used for sanding the timber floor?

Budget Floor Sanding uses Canadian galaxy drum machines, which are known for their excellent performance in the timber flooring industry. These machines are designed to provide efficient and high-quality sanding results.

How many coats of finish are applied to the timber floor?

Typically, three coats of finish are applied to the timber floor. The first coat is applied and allowed to dry overnight. Before applying additional coats, the floor is finely sanded using a buffering machine to create a smooth surface.

What options are available for floor finishes?

Budget Floor Sanding offers a range of floor finishes to suit different preferences. These options include gloss, satin, and matte finishes. There are also choices between solvent-based, polyurethane, environmentally friendly water-based, and traditional oil-based finishes.

Can damaged floorboards be repaired or replaced during the sanding process?

Yes, if there are damaged floorboards, Budget Floor Sanding can repair or replace them as part of the sanding process. This ensures that the final result is a smooth and uniform floor surface.

How are color variations between replacement floorboards and the original ones addressed?

Floorboard replacement is carried out with careful color matching in mind. Similar colored timber floorboards are sourced, and if any color variations occur, wood floor staining is performed to blend the new floorboards with the surrounding original ones. This attention to color matching ensures a seamless and cohesive appearance.

How long does the floor sanding and polishing process typically take?

The duration of the floor sanding and polishing process depends on various factors, including the size of the area, the condition of the floor, and the number of coats applied. Generally, the process takes around 3 to 4 days to complete. This allows for thorough sanding, drying time between coats, and the application of multiple coats for a durable and beautiful finish.

What is timber floor sanding, and why is it required?

Timber floor sanding is the process of removing the top surface layer of a wooden floor and revealing a fresh layer underneath. It is necessary for floor restoration, eliminating imperfections and damages.

What is involved in the floor polishing process?

Floor polishing involves the application of a protective finish to the sanded timber floor. This finish uplifts the natural beauty of the wood and provides durability and protection. Multiple coats of finishing are applied, such as water-based or oil-based polyurethane, natural oils, or waxes, followed by buffing for a smooth finish.

How often timber floors should be sanded and polished?

Floors should typically be sanded and polished every 10 to 15 years, depending on the amount of wear and tear they experience. High-traffic areas may need attention sooner, while low-traffic areas may last longer before needing it.

How much does it cost to sand and polish timber floors in Brisbane?

Timber floor polishing and sanding costs vary, depending on the size of the area, the condition of the floor, and the type of finish used.

- On average, the price in Brisbane can range from $25 to $50 per square meter.

- Factors such as extra coats, extensive repairs, or using special finishes can increase the overall cost.

Is the process of sanding dust-free?

Modern sanding machines are designed to have built-in dust collection systems, making them dust-free. These systems capture most of the dust but are not 100 % dust-free. The use of the dustless sander minimizes the spread of dust and improves air quality.

How polished timber floors can be maintained?

Newly polished timber floors require special care and maintenance.

- Use area rugs and mats in high-traffic areas and clean spills immediately to avoid moisture damage.

- Avoid using harsh chemicals on the polished surface for cleaning. Regular dusting mitigates the need to clean the floor with chemicals and cleaners.

Can all timber floors be sanded and polished?

- Most timber floors can be sanded and polished multiple times but, some older or damaged floors require repair and professional inspection before sanding.

- Engineered timber floors with a thick top layer of hardwood can be sanded for few times.

How long should we wait before walking on the floor after polishing?

The waiting time before you can walk on the floor after polishing depends on the type of finish used. For water-based finishes, you can usually walk on the floor 24 hours after the final coat is applied, for oil-based finishes, wait 2-3 days before walking on the floor.

What is the difference between water-based finishes and oil-based finishes?

- Water-based polyurethane finishes dries faster than oil-based. They are eco-friendly and have low VOCs. Unlike oil-based finishes, they do not change the original color of the timber.

- Oil-based polyurethane takes longer to dry (6-12 hours) and releases more VOCs during application. They give a warm amber tone to the wood.

Is it feasible to sand timber floors during the rainy season?

Timber floors can be sanded in Brisbane’s rainy or humid season, but it’s important to monitor moisture levels in the timber before, during, and after sanding.

How long does new floor polishing last?

- The longevity of floor polishing depends on various factors such as the level of foot traffic, maintenance, and the type of finish used.

- In low-traffic areas, the finish can last up to 10-15 years, while in high-traffic areas, the finish may need to be refreshed every 3-5 years.